Double Planetary Mixer DPM

Double Planetary Mixer

Germany travels far, every day is new, and excellence is reached.

Application fields:Adhesives, lithium batteries, composite materials, etc.

Product overview

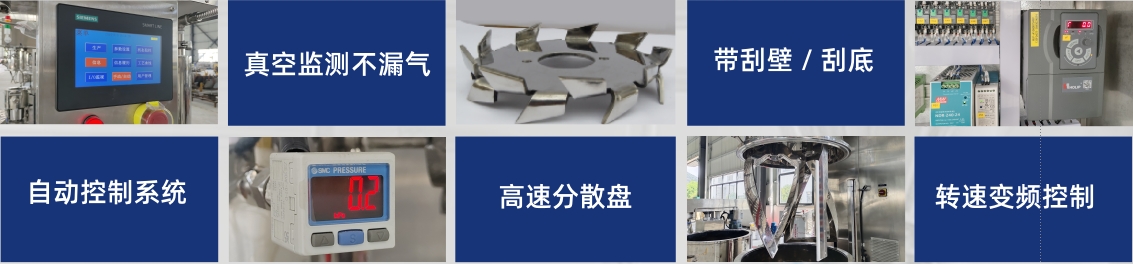

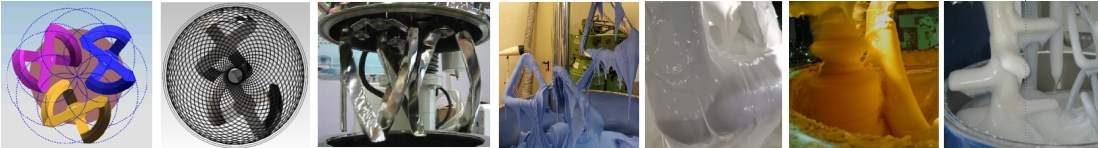

• Two or more sets of vertically arranged low-speed stirrers (such as helical paddles) installed on the stirring shaft drive the material to produce strong kneading, rubbing, and up/down/left/right circulation movements (from a macroscopic perspective, causing the material to collide, exchange, extrude, knead, wet, and circulate, achieving functions such as mass transfer, heat transfer, and reaction); ensuring that the material is fully and evenly mixed (good dispersed and distributed mixing effect). If a high-speed shear dispersion disk is added, it can produce strong mechanical and hydraulic shear effects, fully and deeply breaking up agglomerated particles.

• Low-speed stirrer shapes: can flexibly choose from paddle type, frame type, butterfly type, helical type, etc. Applications: adhesives, lithium batteries, composite materials, etc.

Product Parameters

|

Serial Number |

Model |

Working Volume |

Remarks |

|

1 |

DPM-2 |

1L |

Cantilever Type |

|

2 |

DPM-5 |

3.5L |

Cantilever Type |

|

3 |

DPM-8 |

5L |

Cantilever Type |

| 4 | DPM-16 | 10L | Cantilever Type |

|

5 |

DPM-30 |

20L |

Cantilever Type |

| 6 | DPM-45 | 30L | Cantilever Type |

| 7 | DPM-60 | 40L | Cantilever Type |

| 8 | DPM-90 | 60L | Cantilever Type |

|

9 |

DPM-140 |

100L |

Cantilever Type |

|

10 |

DPM-200 |

150L |

Cantilever Type |

|

11 |

DPM-300 |

200L |

Cantilever Type |

|

12 |

DPM-400 |

300L |

Cantilever Type |

|

13 |

DPM-500 |

400L |

Cantilever Type |

|

14 |

DPM-650 |

500L |

Cantilever Type |

|

15 |

DPM-825 |

650L |

Gantry Type |

|

16 |

DPM-1000 |

800L |

Gantry Type |

|

17 |

DPM-1300 |

1000L |

Gantry Type |

|

18 |

DPM-2000 |

1500L |

Gantry Type |

|

19 |

DPM-2500 |

2000L |

Gantry Type |

| 20 | DPM-4000 | 3000L | Gantry Type |

Pre-sale, sale to after-sale, professional team one-stop service for you

More models can also contact us to support customization

Understanding needs

Talk to you in detail, tell us your needs

02

Manufacturing

We will complete the quality and quantity within a reasonable time.

04

Technical Installation

On-site installation and commissioning to stable production

05

Post-maintenance

If you have any problems in the later period, please contact us after sales.

06

Related Products

Vertical Kneading Machine HVKM

Two sets of vertically arranged spiral double-sided intermeshing blades installed on two stirring shafts rotate in opposite directions, causing the material to continuously move from the side walls of the mixing barrel towards the center of the mixing barrel or in the opposite direction. The two sets of blades constantly adhere to and peel away from each other, forcing the mixed material to undergo intense shearing, kneading, folding, pressing, and stretching actions within a small range. The increase and decrease of pressure and shear force can promote the material to achieve optimal dispersion of intensive mixing and kneading in a short time.

The serrated circular dispersion disc of the high-speed and efficient disperser completes the solid-liquid dispersion, wetting, deagglomeration, and stabilization processes at high speed within the container. This causes the slurry to form a rolling annular flow, generating strong vortices, with particles on the slurry surface spiraling down to the bottom of the vortex; a turbulent zone is formed at the edge of the dispersion disc at 2.5-5mm, where the slurry and particles are subjected to intense shear and impact; outside this area, two streams are formed above and below, allowing the slurry to circulate and flip fully; below the dispersion disc, the slurry is in a laminar flow state, with layers of slurry at different flow rates diffusing into each other to achieve dispersion.

Widely used in the mixing, kneading, crushing, stirring, and re-polymerization of high viscosity and high elastic-plastic materials, such as sealants, silicone rubber, glass glue, silicone, organic silicon, gasket glue, modified starch, chewing gum, bubble gum, pulp, cellulose, batteries, inks, pigments, dyes, pharmaceuticals, resins, plastics, vulcanized rubber, cosmetics, CMC, adhesives, and other industries.